A sophisticated solution

The functioning principle of the MFSR combined performs all necessary demoulding and shuttering functions of a pallet circulation plant. This solution is designed for plants with a performance of up to 100 m2 / hour. This compact design enables installation in existing plants also and is an alternative investment for plotter, cleaning, plotting and oiling machines.

With this state of the art solution quality and productivity will be improved and staff does not have to do exhausting and dangerous work, anymore. With a production rate of 800m2 about 10,000 kg shutterings are transported. The perfect task for the MFSR.

The functioning principle

The shutterings lie unarranged with open or closed magnetic units on the pallet.

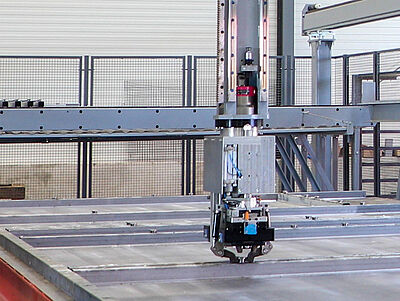

MFSR scans the pallet. The position data of each shuttering are calculated.

MFSR gripping unit graps shutterings and transfers them to the shuttering transport and cleaning unit.

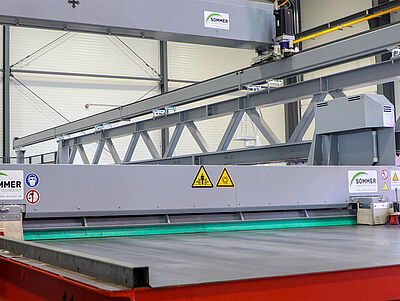

After all shutterings have been taken away the pallet is cleaned with a driveable cleaning machine.

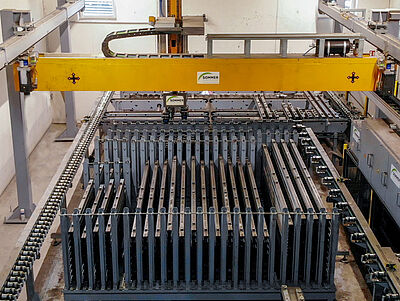

During that period the MFSR manages the shutterings in the active and passive magazine.

Oiling of shuttering area to be casted.

Drawing (plotting) of shutterings and insert parts not to be placed automatically.

Placing of shutterings, aligning them, activating of magnets.

Advantages

- Reducing of costs for staff

- Staff has not to do exhausting and dangerous work anymore

- Avoiding of risks of accidents

- Smooth handling of shutterings

- Reduction of investments

- High acceptance with members of staff

- Saving of forming oil

Functions

- Measuring of pallet on the side shuttering

- Shuttering and magnet calculation

- Picking up of shuttering profiles from active and passive magazine and accumulating conveyor

- Placing of longitudinal and cross shutterings with integrated magnets and activating of magnets

- Automatic gap optimization and aligning of shutterings on the push edges

- Scanning of the pallet

- Recognizing and caluculating of shutterings profiles and magnets

- Opening oft he integrated magnetic fixing system in shuttering profiles and magnetic boxes

- Automated pick-up of dirty shutterings and magnets with feeding to cleaning machine afterwards

- Placing of additional magnets for insert parts or frames (standard magnets, insert part magnets, and magnetic boxes)

- Plotting of outlines and recesses and symbols

- Oiling of pallet surface to be casted

- Per element the surrounding ashlar is calculated, enlarged by a side distance and driven in curves.

- The roboter takes the labeling unit from the magazine and performs the attaching of labels in one process

- The robot can place all additional elements to be fed automatically on the corresponding positions.

- Management of shutterings in passive magazines

- All required additional components for the trouble-free and automated operation are adapted in modules according to the requirements of the customer.

- Shuttering transport lines, cleaning devices, active magazine as chain or step conveyor and passive magazine with rebuilding stations have improved in use and guarantee an economic production as do all Sommer products.

Options of use

The systems are adapted in modules according to requirements. Corresponding to defined sample pallets the cycle times can already be simulated in the planning stage of the project. From this calculations the configuration of the plant arises.

CYCLING TIMES

The highly dynamic system enables movement and acceleration times to meet all requirements.