WCS

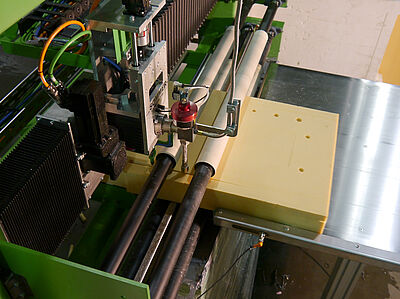

The WCS, a SOMMER patent pending new machining centre, enables continuous processing of standard panels.

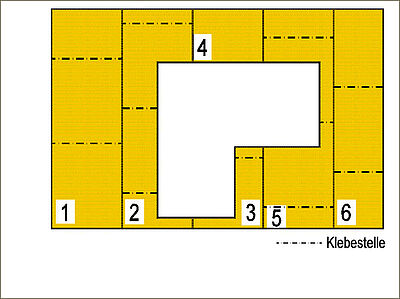

The cutting of openings, bores and contours in variable geometric shapes and sizes in different materials is fulfilled according to the CAD data.

The machining of the material happens in a continuous process. The material is continuously conveyed to the cutting unit. The WCS -Machining centre enables endless processing and automated production, with an optimized cutting scrap, of individual panels.

THE WATERJET CUTTING SYSTEM (WCS) CAN BE DELIVERED IN 3 DIFFERENT VERSIONS:

WCS – with 6-axis industrial robot

All processes within the given cycle times.

The configuration is made according to customer requirements and it is modular.

- Reception of full panels

- Reception of sectioned panels

- Reception of wall connectors

- Insert of wall connectors

- Operations alternately (Panel – Connectors – Panel)

- Magazine for wall connectors on the X axis

- Changing magazine for wall connectors

- Exchange of wall connectors magazine

TECHNICAL DESCRIPTION:

The material is assembled in order to form an endless panel and will be then supplied to the cutting unit.

The panel is referenced. The synchronized running driver units are pressed on the material and lead the panel through the cutting unit. This continuous process allows a minimum sectional area. The noise and emission range as well as the beam catcher are reduced to a minimum.

The maximum panel length is adapted to the customer requirements. The maximum panel thickness is designed from 2 mm up to 200 mm. The panel width from 10 mm - 1.250 mm.

The system was developed for cutting insulation panels used in concrete sandwich elements. However, it is also ideally suited for cutting all other panel materials. The accuracy of the WCS-Processing unit is in the range of +/- 1 mm and depends on the material and cutting speed.

The cutting pressure and the selection of cutter between pure water and abrasive are adjusted or adapted according to the task. Adjustable high-pressure pump technology with up to 6200 bar cutting pressure allows an almost unlimited variety of materials to be machined.